galvanized iron paint suppliers

To facilitate the use of flax yarn in their designs, Tin Can Knits collaborates with several reputable suppliers who prioritize ethical sourcing and quality production. These suppliers often have a transparent supply chain, ensuring that the flax fibers used in their yarns are grown and processed in a sustainable manner. By partnering with such suppliers, Tin Can Knits can confidently promote patterns that utilize linen and flax yarns, knowing they are supporting responsible practices.

tin can knits flax suppliers

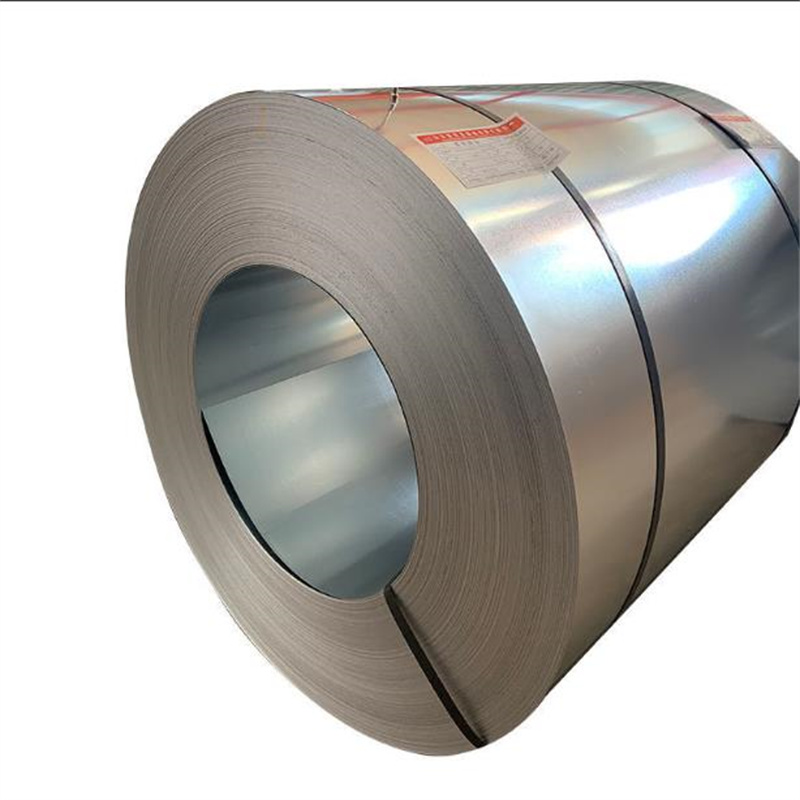

Typically, galvanized iron sheets are available in various thicknesses measured in gauges. The most common standards range from 18 gauge (approximately 1.2 mm) to 26 gauge (approximately 0.5 mm). Thicker sheets, like 18 or 20 gauge, are commonly used in applications requiring structural strength, such as construction and industrial settings. In contrast, thinner sheets are often applied in manufacturing and household fixtures where weight and flexibility are crucial.

High pressure vertical pumps are designed to handle fluids at high pressures and are often used in applications where space is limited. These pumps are typically installed vertically, which allows them to have a smaller footprint compared to their horizontal counterparts. The vertical design is particularly advantageous in environments where floor space is at a premium, such as in high-rise buildings or industrial plants with constrained layouts. These pumps are known for their ability to deliver high pressure with minimal energy consumption, making them an efficient choice for systems that require constant, reliable pressure. By optimizing the design of high pressure vertical pumps, engineers can ensure that these pumps provide robust performance in demanding applications.